Wind turbine manufacturing requires versatile solutions with the ability to cut and maneuver the long and short reinforcement panels typical to blades, nacelle housing, and spinners. Even when cutting large pieces, tolerances remain low. The best cutting and material handling solutions can effortlessly manage the multitude of materials necessary for turbine manufacturing. As countries rely more heavily on renewables, the wind energy industry is advancing quickly. Manufacturing facilities must evolve to keep up with innovative materials and processes, as well as demand.

Eastman Machine Company’s solutions offer precision and versatility, making them an industry favorite for cutting and handling the multiple materials, shapes, and sizes required for wind turbine blade and body construction. At Eastman, you’ll find a wide range of equipment and experience specific to cutting the flexible composites and core materials common in the wind energy industry. Our application specialists have significant experience with (but not limited to):

- Flexible composites: fiberglass, carbon fiber, aramid, etc.

- Core materials: foam core, balsa, thermoplastics, Coremat®, etc.

Cutting Solutions for Wind Turbine Manufacturing

When you choose an Eastman for your cutting and material handling needs, you’re opting for machines backed by experienced product engineers and a history of high performance. Eastman Machine offers cutting solutions for renewable energy manufacturing that are: simpler to operate; less expensive to maintain; and customized to cut and handle technical materials.

Contact us to discuss your unique wind energy application requirements.

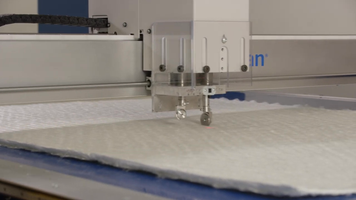

Automated Cutting Machines

Computer-controlled cutting machines offer reliability, accuracy, repeatability, and flexibility. These characteristics provide numerous benefits when constructing fiberglass wind turbine blades and other wind energy components. Automated cutting machines can reduce reliance on manual labor, use expensive composite materials more efficiently, improve quality and throughput, minimize handling, and decrease time to market.

Eastman offers digital cutters in multiple configurations to meet your needs, including custom cutting surface lengths and widths. Our tool head, powered by a brushless servo motor and independently controlled air supply, is available with two or three spindles. These spindles can be outfitted with over 60 blades, punches, and notches including a round knife, 10-sided blade, and drag knife designed for a wide variety of wind energy materials and patterns. An inkjet or airbrush printer can also be integrated into the Eastman Tool Head.

Material Handling Solutions

Cutting fiberglass and other wind energy-specific materials is only part of the manufacturing process. Large, yet delicate, turbine components must be moved to and from the cutting surface with specialized material handling solutions.

Eastman offers feeding systems that convey rolled material with consistent speed and suburb control. Our material handling equipment also includes rewinders for increased efficiency and damage-free transfer of cut materials from our conveyor cutters. This solution allows manufacturers to manage long cut pieces and corresponding waste, especially when the pieces exceed the table length and become difficult for operators to collect manually.

Manual Cutting Machines

For facilities with space, power, or budget restrictions, Eastman also offers manual cutting solutions. Time-tested and industry-proven, our manual cutters can be used for a wide variety of materials. Air-powered options are available for wet environments.

Technical Support

Every Eastman is backed by lifelong customer service and technical support. Our team will work with you and your materials, beginning with test cuts and customized configurations. After installation, you’ll have access to ongoing support around the clock and throughout the world. Contact our support team any time for troubleshooting, servicing, and consumables.

Industry Approved

Wind turbine manufacturers must meet strict industry standards that ensure the performance and reliability of their end products. We offer a variety of industry-approved accessories for your Eastman.

Meet or exceed guidelines with Eastman’s inks for high-speed printing as well as sealed control and computer enclosures for dust and water-resistant protection in harsh or high particulate environments. Our cabling connectors, servo motors, and display components meet recognized international protection rating requirements as well.

Product Videos

Eastman automated cutting machines take on a variety of materials commonly used in wind energy, including fiberglass and other flexible composites.

We’re here to help.

Our global team is ready to answer your pre- or post-sales questions. You can reach the experienced professionals at Eastman by calling +1 716-856-2200. To have one of our team members contact you, use the button below.