Innovation is the buzzword of the sewn products industry, with new trends and technology in materials, manufacturing, and marketing. As companies continue to navigate a global economy changed by COVID, they’re finding that while many things have changed, some have also stayed the same.

The vast majority of sewn products continue to utilize time-tested materials, including polyester, cotton, viscose, silk, wool, and leather. Manufacturers must continue to optimize their businesses to create reliable supply chains, adapt to labor shortages, minimize waste and maximize efficiency. Simultaneously, manufacturers in the apparel, upholstered furniture, home textiles, transportation interiors, and leather goods industries must adapt to meet consumers’ increased expectations for sustainable, high-tech, and luxury goods.

These demands require strategic planning and forward-thinking. They also require the right equipment, backed by responsive partners. Eastman Machine Company is proud of its sewn products heritage. It was our founder who created the first electric cloth cutting machine in 1888. In the generations since, our commitment to innovative cutting solutions and customer service has never wavered. We continue to support sewn products manufacturers as they balance continued improvement and disruptive innovation shaped by industry trends.

High Volume Facilities

Manufacturing facilities in the business of making clothes, home textiles, and leather goods (generally) output at high volumes to meet demand. At the same time, consumer and economic demands are placing additional pressures on these facilities to operate efficient, minimal waste cutting rooms while producing goods in a wider range of sizes and styles. Heightened expectations for affordability, sustainability, inclusivity, and personalization are not unique to the sewn products industry. The industry, like many others, is also currently navigating COVID’s lasting impact on the supply chain and labor market.

Trending Textiles

Designers, engineers, marketers, and other sewn products professionals are also searching for ways to stand out in crowded markets. Innovative materials are one way to meet customers’ demands and gain a competitive advantage. These materials fit, loosely, into three categories: sustainable, high-tech, and premium fabrics.

Textile manufacturers are approaching sustainability in a variety of ways. Perhaps the most straightforward approach is improving the practices used to grow existing natural fibers and manufacture them into fabrics. Other opportunities involve alternative natural fibers (like hemp, flax, and bamboo) and cellulose fibers that can be recycled endlessly, such as HeiQ AeoniQ.

Consumers spending more time at home during the first waves of the COVID-19 pandemic prioritized the quality of the textiles in their clothes and home. These preferences still exist, even as more of their disposable income is spent on out-of-home experiences. High-tech and luxury materials are helping sewn products manufacturers meet the continued demand for premium fabrics. Electronic components embedded into intelligent fibers allow the material to process and store data. Textiles like brrr° Pro, which offers cooling and wicking properties, are designed with a specific user in mind—in this case, athletes and trainers.

Even utilitarian workwear is getting a high-tech makeover. Smart textiles are keeping workers safe with properties such as flame resistance, comfort in extreme conditions, and antiviral finishes. Protective workwear is becoming more accessible, like C2R’s military-grade apparel designed for outdoor enthusiasts. Workwear textile manufacturers are also cognizant of the environmental impact of their materials. Cordura® mill partner C.F. Weber is now using re/cor recycled nylon 6.6, which offers both sustainability and durability.

Both apparel and home textiles manufacturers are utilizing traditional premium fabrics, including silk, linen, cashmere, wool, and leather. The sustainability and premium trends have collided as well, with materials like Mylo™, a leather alternative made from mushrooms.

Cutting Room Challenges

As consumers require more from their sewn goods, manufacturers must invest in equipment that allows them to meet these expectations. Existing challenges remain; cutting machines must offer high throughput on traditional materials ranging from silk to denim with little-to-no waste. The right equipment will also help manufacturers remain efficient and effective through labor shortages and supply chain concerns.

With the addition of innovative textiles, cutting room challenges are magnified. Now, cutting and handling equipment must adapt to alternative materials that may not behave exactly as traditional yarns do. As fabrics become more innovative, material costs generally increase, making intricate nesting and precise cutting even more important.

Because continuous improvement and disruptive innovation are occurring simultaneously, cutting machines must also be able to quickly adjust to cut both traditional and more technical textiles without sacrificing the speed and reliability required in high-volume production.

Meeting Challenges with Eastman

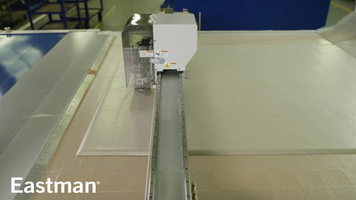

Eastman Machine Company has been helping sewn products manufacturers adapt to shifting trends for decades. The Talon Multi-Ply is designed to cut up to 7.5 centimeters (3 inches) of compressed material goods at speeds up to 40 inches per second. The Talon is just one piece of an automated, connected cutting room that can help companies improve accuracy, reduce reliance on manual cutting, and maximize material usage.

The Talon can be outfitted with a variety of cutting implements, including a straight knife (with one or two drill attachments) or a drag knife. Additional machine options include:

- Takeoff display

- Knife cooling

- Pen/marking tool

- Diagnostic camera

- Knife breakage sensor

- Thermal label printer

- Surface re-sealer

- Bar code scanner

Eastman is constantly improving attachment options to meet industry needs for versatility and adaptability without compromising the accuracy, speed, or repeated quality high-volume production environments require. In high-output facilities, reliability is also paramount. The Talon uses Eastman’s Recipro-CoolTM Drive Assembly to reduce wear and tear on the tool head’s mechanics. The bristle-block conveyor bed can withstand 2,000+ hours of normal operation; a modular design allows facilities to quickly and easily repair damaged sections.

A powerful software suite drives the Talon and other automated Eastman cutters. Maximize material usage with patternPRO, our design and nesting software, and visionPRO, designed for accuracy on printed fabrics. Enhance productivity with EasiSelect (specifically designed for high-volume applications) and meet industry 4.0 standards with OPC UA.

Together, the Talon (a high-ply conveyor cutting machine), industry-specific software, and material handling solutions deliver a versatile, innovative cutting system that can be tailored to any sewn products manufacturer’s specifications, whether it’s working with dainty silk or rugged denim. A cutting room backed by Eastman’s diverse experience and technical support—from test cuts to customer service—is positioned to successfully navigate a changing industry.