Manufacturers have a multitude of reasons to design with fiberglass as a primary material for their products. Its versatility, strength, and insulating properties, along with its ability to resist corrosion from both water and chemicals, make it a low maintenance, long-lasting composite option. These qualities make glass fiber composites the material of choice for many industries, including marine and alternative energy applications.

Glass fibers are created by melting silica sand, limestone, and soda ash together and shaping the resulting liquid into fibers. The fibers can be either discontinuous (like those found in insulation) or continuous and woven into fiberglass fabrics. The fibers, assembled in various orientations, stay together thanks to the fibers themselves or mechanically stitched, non-structural threads. To manufacture the fiberglass panels often used in the marine and wind energy industries, these fabrics are impregnated with a resin and cured to form a strong, versatile composite.

In order to utilize fiberglass to its fullest potential, manufacturers must choose the right fiberglass cutting tools for their applications.

The Challenges of Cutting Fiberglass

While designing with fiberglass offers unique advantages, cutting and handling the material can pose challenges. The strength of fiberglass, as well as the demands of marine and wind energy manufacturing environments, means that your chosen cutting tool must be both durable and reliable. The right fiberglass cutting tools must be capable of cutting dry, wet, coated, or impregnated woven and multiaxial reinforcements and chopped strand mat. Fiberglass is available in many orientations—unidirectional, bidirectional, multiaxial, or random—and each construction method may impact the speed, throughput, and blade type necessary for your cutting system.

Industrial Fiberglass Cutting Solutions

Many industries, in both commercial and hobby applications, use glass fiber because of its versatility. It can seem as though there are just as many cutting solutions available as there are unique uses for fiberglass. Choosing the right cutting tools for your facility is easier with the help of Eastman’s experienced engineers and unmatched customer service.

Automated Fiberglass Cutting Machines

Choosing an automated, computer-controlled cutting machine allows manufacturers to balance output, speed, and accuracy. It also reduces manual handling, increasing operator safety. Consider the variety of composite materials you cut and the volume of each when deciding on the best tool to cut fiberglass at your facility.

To learn more about throughput and volume production of fiberglass with Eastman automated systems, check out the Fiberglass Brochure.

C125 Conveyor System

Eastman’s C125 Conveyor System is designed to cut a single glass fiber roll continuously. The machine’s reliability allows manufacturers to cut at a high speed for hours at a time for high-volume output. If your cutting files require an entire roll—or more—of single- or low-ply fiberglass textiles, the C125 may feel right at home on your manufacturing floor. Even with the ability to output around 1.8-ton of fiberglass per hour when cutting four-ply (including time for material loading and cut patterns collection), this automated fiberglass cutting solution is more accurate than cutting by hand.

S125 Static Table Cutting System

For a superbly accurate cut, choose the S125 Static Table Cutting System for your fiberglass. While this cutting solution requires a more manual approach, it also allows for switching between materials with ease. You won’t sacrifice speed for accuracy with the S125; at speeds of up to 60 inches per second, this fiberglass cutting machine offers the same capabilities as the C125 Conveyor System on a static surface.

Talon Multi-Ply

The Eastman Talon is the best fiberglass cutting tool for industrial applications that require high volume outputs. The Talon’s ability to cut massive amounts of fiberglass in multiple plies makes it an indispensable member of many manufacturers’ production floors. The Talon ensures quality cuts of glass reinforcement from top to bottom ply. It does so by utilizing an industrial, serrated-edge reciprocating blade coupled with patented knife control software.

Customizing Your Cutting Solution

Eastman Machine Company designs, manufactures, and supports its automated cutting solutions from its US headquarters. This distinct advantage allows Eastman to provide personalized customer service, from recommending the best fiberglass cutting tools for your application to minimizing downtime with US-based lifetime support.

Finding the right tool for your application starts with our complimentary test cut evaluations. The test cut uses your materials and patterns to determine the best configuration. Our engineers have developed a wide variety of customized solutions for facilities cutting glass fiber, from tool heads to material handling.

Tool Heads

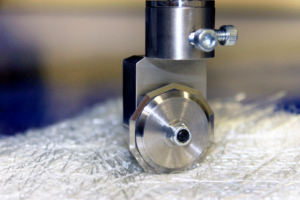

For increased production flexibility and minimized downtime, many manufacturers cutting fiberglass opt for Eastman’s Heavy-Duty Tool Head. This unique tool head utilizes its own brushless servo motor and air supply. This technology allows the head to alternate between two different tools. Along with two cutting spindles, operations can also include a marking pen, rotary blades, notching tool, drag-style knife, or punching tool. An uninterrupted cut file can use any combination of cutting and punching tools, as well as the marking pen.

Eastman’s Standard and Fiber Tool Heads are also viable solutions, depending on the type of glass fiber you’re cutting.

Cutting Blades

Eastman recommends cutting fiberglass with a round blade in most applications. By design, the blade easily crushes and breaks materials containing glass fibers. Increased cutting pressure extends the life of the blade. Compared to reciprocating blades, a round blade cuts glass fiber with less fragmentation.

Fiberglass can also be cut with a 10-sided blade, which is engineered to cut advanced textiles like stitched fiberglass. This blade offers maximum versatility and adaptability when added to a heavy-duty tool head.

Material Handling

The right fiberglass cutting solution goes beyond the cutting tool itself. Eastman designs installations that include feeding systems and other material handling options for your production floor. Our feeding systems allow manufacturers to introduce rolled fiberglass textiles to the cutting table with accuracy and control, streamlining the production process. If you’re managing long cut pieces of glass fiber inputs, adding rewinders can minimize the need for manual labor. This is particularly helpful when cut parts exceed the table length and become difficult for operators to handle manually.

Marking Systems

Additional cutting system options include marking systems, which print part identifications and sewing directives directly onto the material you’re cutting. For fiberglass, which may not allow for traditional printing, Eastman recommends the EasiMark® airbrush marking system or JetPRO(r) drop-on-demand inkjet printers for high speed, no-contact printing.

Manual Fiberglass Cutting Tools

The range of manual cutting tools suitable for cutting reinforcement fibers is just as robust as Eastman’s line of automated solutions. Straight knife cutting machines, like the Blue Streak II®, offer an industrial solution for stack cutting woven roving, biaxial reinforcements, and chopped strand mat. Eastman’s Buzzaird is an air-powered alternative for facilities where electric power is not sustainable. This fiberglass cutting tool includes several blade options to shear, chop, or slice through various technical fabrics and composite reinforcements.